With environmental pollution becoming increasingly serious, air quality issues have become the focus of global attention. Recently, a research result published in the journal Nature has brought us good news - scientists have used nanocarbon materials to improve air filters, effectively improving the adsorption and detection capabilities of particulate matter in the air.

This breakthrough not only provides new ideas for improving air quality, but also brings hope for human health and environmental protection.

Air pollution, a global problem, not only threatens human health, but also has a serious impact on ecosystems and the earth's climate system. From industrial emissions to traffic exhaust, the impact of pollutants generated by human activities on air quality cannot be underestimated. Among them, particulate matter (PM) has attracted much attention due to its potential harm to human health and the climate system.

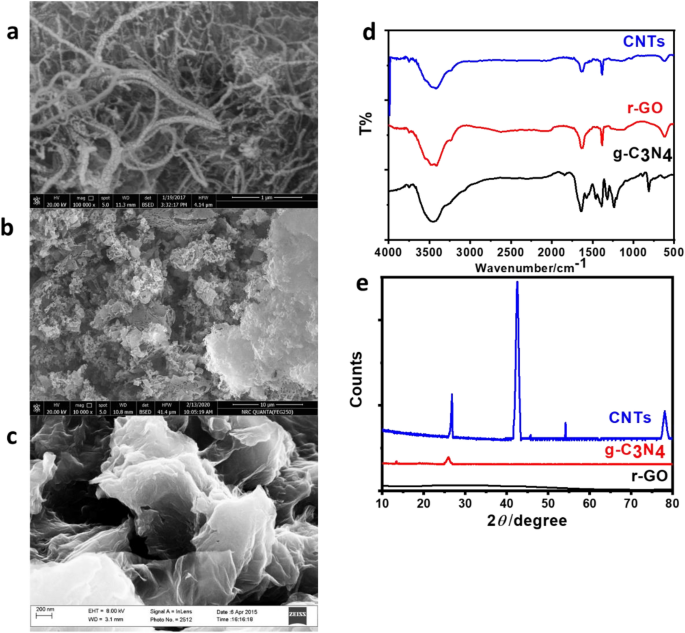

In this study, scientists turned their attention to nanocarbon materials, including carbon nanotubes (CNTs), reduced graphene oxide (r-GO) and graphite phase carbon nitride (g-C3N4). These materials have shown great potential in the field of air purification due to their unique physical and chemical properties. The research team explored the effects of these nanomaterials on improving the adsorption efficiency of filters by applying them to filters for air particle monitoring equipment.

The experimental results are encouraging. Through electron microscope images, we can see that the diameter of CNTs is between 40-50 nanometers and the length is about 20 microns. While g-C3N4 presents a typical layered stacking structure, r-GO nanosheets show an irregular folded layer structure. The high specific surface area and tunable surface chemical properties of these nanomaterials make them excellent in adsorbing heavy metals in the atmosphere.

In the study, scientists used three techniques: energy dispersive X-ray spectroscopy (EDX), inductively coupled plasma mass spectrometry (ICP) and laser induced breakdown spectroscopy (LIBS) to analyze the filters. The results showed that the filters modified with nanomaterials performed far better than unmodified filters in adsorbing particulate matter in the air. In particular, CNTs, due to their high active surface area and precise pore size, showed excellent adsorption capacity.

In addition, the application of LIBS technology provides a new sensitive method for heavy metal monitoring. Compared with the results of traditional ICP analysis, LIBS showed high consistency in the analysis of sodium, zinc and copper, although there were some differences in the analysis of manganese. These findings further confirm the potential of nanomaterials in improving filter efficiency.

This study not only proves the application prospects of nanocarbon materials in the field of air purification, but also provides a new direction for future environmental governance. With the advancement of science and technology and the deepening of research, we have reason to believe that these nanomaterials will play an increasingly important role in environmental protection and human health.

Air pollution control is a protracted battle, but every technological advancement brings us new hope. The application of nanotechnology has allowed us to take another solid step on the road to fighting air pollution. Let us look forward to these innovative technologies entering our lives as soon as possible and contributing to our blue sky and white clouds.

References:

Nano carbon-modified air purification filters for removal and detection of particulate matters from ambient air

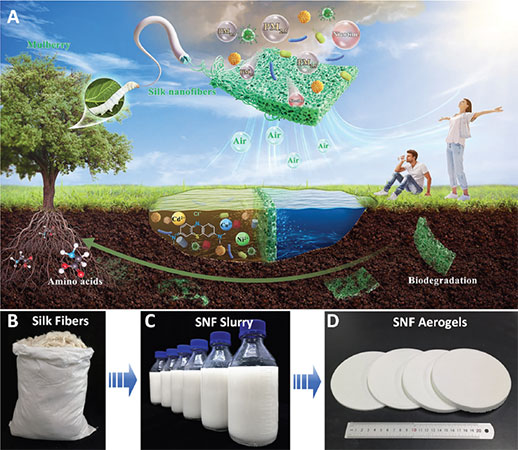

As environmental pollution becomes increasingly serious, people's demand for clean air and water becomes more urgent, which has promoted the rapid development of the filter material market. However, traditional petroleum-based filter materials are difficult to degrade after use and are prone to secondary pollution. It is urgent to find environmentally friendly alternatives. The silk nanofiber (SNF) aerogel developed by the Wuhan Textile University team has become a new focus in the field of materials science and environmental protection with its excellent air filtration performance and sustainable characteristics.

Unique structure lays the foundation for filtration performance

The preparation of SNF aerogel is based on solvent-mediated ice crystal growth technology, which can produce large aerogels with adjustable structures on a large scale. By adding a small amount of chitosan to SNF, the mechanical properties and water resistance of the aerogel are significantly improved, so that it can also play a stable role in complex and changeable actual environments.

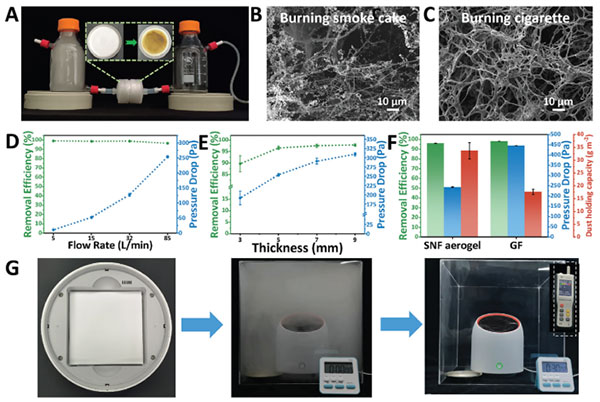

The three-dimensional porous network structure of the aerogel, which is interwoven by a large number of nanofibers, provides a physical basis for efficient air filtration. The tiny nanofibers can effectively intercept tiny particles in the air, while the porous network ensures the smooth flow of air, avoiding the influence of excessive resistance on the filtration effect, and achieving a good balance between filtration efficiency and air circulation.

Efficient filtration of air pollutants

In terms of air filtration, SNF aerogel has demonstrated extraordinary capabilities. It can efficiently filter air pollutants such as PM0.3 and smoke. PM0.3 is a fine particle that is extremely harmful to human health, and traditional filter materials have limited filtering effects on it.

SNF aerogel, with its nano-scale fiber structure, can accurately capture these tiny particles, greatly reducing the concentration of particulate matter in the air and creating a healthier breathing environment for people. Whether it is a large amount of smog generated by industrial emissions and automobile exhaust in the city, or harmful gases and particles such as secondhand smoke indoors, SNF aerogel can effectively filter them. Its filtering effect has been fully verified in relevant experiments, providing strong support for improving air quality.

Sustainability advantages help environmental protection

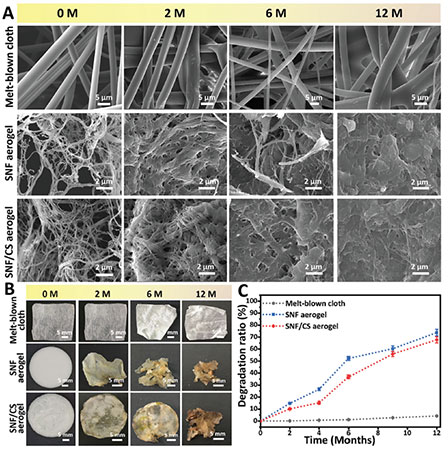

Compared with traditional petroleum-based filter materials, the sustainability advantages of SNF aerogel are particularly prominent. In the natural environment, SNF aerogel is safely biodegradable.

Commercial PP meltblown cloth basically does not degrade after one year of landfill, while the degradation rate of SNF aerogel waste after direct landfill is over 70%, greatly reducing the long-term pressure of waste on the environment. This feature not only fits the current environmental protection concept, but also conforms to the development trend of future filter materials, providing a new idea for solving the environmental problems of filter materials.

In air filtration applications, the use of SNF aerogel can effectively reduce environmental pollution caused by the replacement and disposal of filter materials, and achieve the dual goals of air purification and environmental protection.

Silk nanofiber aerogel has shown great potential and value in the field of air filtration due to its unique structure, high-efficiency air filtration performance and excellent sustainability. In the future, KLC will continue to innovate, explore, upgrade production processes, and improve quality, and make positive contributions to the development of the global low-carbon economy and the construction of green ecological civilization.

The research team of Shandong Provincial Key Laboratory of Medical and Health Textile Materials has developed a new type of nanofiber membrane that can still efficiently filter pollutants in the air under harsh conditions. The relevant results were published in the journal "Separation and Purification Technology". The composition of industrial waste gas is complex and harmful, and the development of high-performance air filtration materials is imminent. The ideal filter material should have excellent liquid repellency, resistance to harmful chemicals, and high climate adaptability. To this end, the research team developed a fluorinated metal organic framework (F-MOF) @ polyetherimidehttps://www.klcintl.compolyvinylidene fluoride-hexafluoropropylenehttps://www.klcintl.comfluoroalkylsilane (PEIhttps://www.klcintl.comPVDF-HFPhttps://www.klcintl.comFAS) nanofiber membrane, which shows great potential in personal and industrial protection and air filtration. Preparation of super-liquid-repellent nanofiber membrane The researchers used a multi-needle electrospinning technology to prepare this nanofiber membrane. Simply put, the material solution is stretched into very fine fibers through special equipment and then stacked into a membrane. The main components of this membrane include polyetherimide (PEI), polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) and fluoroalkylsilane (FAS), and a fluorinated metal organic framework (F-MOF) nanoparticles are added to enhance performance. Features of super-liquid-repellent nanofiber membrane This nanofiber membrane has a high porosity of 80% and an average pore size of 2.6 microns, allowing air to pass smoothly while effectively blocking fine particles. It remains stable at a high temperature of 450°C and is not easy to decompose. By adjusting the material composition, the membrane surface has super-liquid-repellent properties, with a water contact angle of 162° and an oil contact angle of 145°. It can repel water and oil, is not easily contaminated by liquid, and has a self-cleaning function. In addition, the membrane has an antibacterial rate of up to 99%, which can effectively prevent bacterial growth. In terms of particulate matter, the super-liquid-repellent nanofiber membrane also performs well, and the filtration efficiency of NaCl and DEHS particles reaches 100% under certain conditions. At the same time, it can still maintain low air resistance during high-efficiency filtration, for example, at an airflow of 10 litershttps://www.klcintl.comminute, the resistance is only 25 Pa. This new nanofiber membrane achieves a combination of super-liquid repellency and high-efficiency filtration performance through a simple preparation process, and can work stably for a long time in harsh environments. KLC

The main materials of clean booth directly affect the cleanliness and effect of clean booth. Whether the maintenance is proper directly affects the service life of clean booth.

What materials are used in clean booth:

1. There are generally three types of frame materials for clean booth: stainless steel square tubes, iron square tubes, and aluminum profiles.

2. There are generally three types of materials for the top of clean booth: stainless steel plates, cold-rolled steel plates sprayed with plastic, anti-static mesh curtains, and organic glass.

3. For the clean air supply part, FFU laminar flow hoods (FFU fan filter units) are generally selected.

4. The enclosure materials of clean sheds generally include: anti-static curtains, (anti-static) organic glass.

The functional definition of the design concept of clean booth has mentioned that "controlling the main production process in a smaller environment is also a choice for clean booth design." In fact, this is the application concept of clean booth, with low investment and control of the main process. Since the control point is higher, the cleanliness level of the clean work booth is generally designed to be very high, generally ISO level 5 and level 4, and a few use level 6.

Clean booth is an air purification equipment for local high clean environment. Clean booth is mainly composed of box, fan, primary air filter, damping layer, lamps, etc., and the outer shell is sprayed. Clean booth can be hung or supported on the ground, with compact structure and convenient use. It can be used alone or connected in multiples to form a strip-shaped clean area.

Clean booth is generally referred to as clean booth, dust-free room, etc. Generally, film enclosure is used, so it is more appropriate to call it clean booth. It is also most appropriate to understand it as clean booth if it is not polluted.

Nowadays, many companies need to produce products in a clean room, such as large food production and processing and electronics production factory. Therefore, many companies are using clean room. The reason why clean room can be dust-free is mainly because a lot of high-tech purification equipment was installed in the clean room during decoration.

1. The air inlet system of clean room must be installed filter box, and a central purification air conditioner (the central purification air conditioner must be divided into three filter sections: primary efficiency /medium efficiency/high efficiency) with a high-efficiency air supply port at the end. It's necessary to install a purification booster box if need.

2. the return air system of clean room must be installed, including a return air outlet, a pre filter, and a middle filter return air box.

3. Enter the buffer zone before entering cleanr room. Electronic interlocks are installed on the buffer zone door, and clean storage cabinets and air fresheners are placed in the changing area. People and goods entering the clean room, must pass through the air shower, cargo shower room, and use pass box to mainly transfer small items.

4. In the clean room, vertical clean bench, laminar flow hood (FFU), clean booth (removable clean booth) and self-purifier should be installed in some places that need to reach level 10-1000. Laser dust particle counter for measuring the cleanliness of clean rooms.

5. The clean room build should be designed with observation windows to facilitate visits.

Clean room equipment:

1、Air shower, changing room and clean room are the three basic components of the workshop purification system. The air shower is a passage in and out of the clean area. The high-speed clean air jetted out can effectively and quickly remove dust and bacteria carried by the human body. The clean room uses interlayer color steel plates to isolate the space and walls, the upper color steel ceiling is suspended, and the floor is paved with epoxy resin.

2、The most important role of air purification equipment in a clean room is to control the cleanliness, temperature and humidity of the atmosphere that products are exposed, so that products can be produced and manufactured in a good environmental space. This space is called a clean room.

3. According to the clean room management regulations, the dust-free purification level is mainly determined based on the number of particles per cubic meter of air that are greater than the classification standard. But for optical structures, a small dose may produce a very large amount, so air purification equipment is needed to build in clean room.

The above content is the purification equipment that needs to be used in the clean room. Different purification levels have different requirements for purification equipment. This mainly depends on the production needs of each enterprise.

Injection-molded magnetic components offer several advantages over traditional magnets. They resist rust more effectively and maintain very precise sizing. Additionally, they can be manufactured into a wide variety of shapes. These parts are produced using specialized molding techniques that combine materials like NdFeB and Ferrite, making them highly versatile for many industries. ZOYN is a leader in this field, providing solutions that meet demanding requirements.

|

Metric/Aspect |

Data/Value |

|---|---|

|

USD 2.5 billion |

|

|

Projected Market Valuation (2033) |

USD 4.2 billion |

|

CAGR (2026-2033) |

6.5% |

Injection-molded magnets provide the advantage of speeding up production and reducing assembly steps. This is why many manufacturers prefer to use them today.

Key Takeaways

-

Injection-molded magnetic components give designers lots of choices. Makers can make complex shapes that help products work better. This also means fewer steps to put things together.

-

These magnets use different materials and binders. This lets makers pick the best mix for strength, heat resistance, and toughness. They can choose what works best for each job.

-

Injection molding keeps magnets safe from rust and damage. This helps them last longer and work well in hard places like cars and medical tools.

-

The process makes parts with exact sizes and smooth surfaces. This saves time and cuts down on waste compared to old ways of making magnets.

-

Injection-molded magnets cost less to make. They can be made quickly and in large numbers. It is easy to add them to other parts. This helps companies make better products faster.

Key Advantages

Design Flexibility

Injection-molded magnetic components give a lot of design freedom. Manufacturers can make shapes that are hard to do with other methods. They can create thin and light parts. Many functions can be put into one part. This helps new ideas in cars and electronics.

-

You can make tricky shapes, like multi-pole inner magnetic rings and sensor housings.

-

Overmolding and insert molding let you mix magnets with metals or plastics in one piece.

-

Engineers can change how magnetic particles are spread and lined up, so the magnet works just right.

ZOYN’s special molding lets them make parts with cool shapes and features. This helps customers bring new ideas to life fast.

This freedom in design means fewer steps and parts. It makes things faster to build and saves money. In cars, these magnets help sensors and actuators work well. In electronics, they make small connectors and speakers possible.

Material Options

Injection molding works with many magnetic and polymer materials. This means makers can pick what fits their needs best.

|

Examples / Grades |

Key Properties / Features |

Application Temperature Range |

|

|---|---|---|---|

|

Magnetic Materials |

Ferrite, NdFeB, SmCo, SmFeN |

Different magnets have different strengths and shapes. Bonded magnets are not as strong but can be made in cool shapes. |

-40°C to 160°C |

|

Polymer Binders |

Nylon 6 (PA6), Nylon 12 (PA12), PPS |

PA6 and PA12 flow well, cost less, and have medium strength. PPS can take more heat, does not burn easily, and is stronger. |

-40°C to 160°C |

Makers choose materials for the right strength, heat, and toughness. PA6 and PA12 are good for many uses and save money. PPS is better if you need more heat resistance. With these choices, magnets can work in micromotors, printer rollers, and car parts.

Mixing different materials in one step is a big plus. It lets engineers control how the product works.

Customization

Customization is a big reason people like injection-molded magnetic components. The mold decides the final shape and size. This makes it easy to make special parts again and again. After molding, machines magnetize the parts to get the right direction, even for multi-pole magnets.

Manufacturers can join magnets with other parts in different ways:

-

Insert molding: Puts a magnet in the mold, then covers it with plastic to hold it tight.

-

Overmolding: Covers the whole magnet, keeping it safe from tough places.

-

Ultrasonic welding: Uses sound to stick two plastic parts with a magnet inside.

-

Snap-on and screw fastening: Uses clips or screws to keep magnets in place.

Extra things like grooves, steps, or covers help keep magnets safe during and after molding. Overmolding and ultrasonic welding can cover the whole magnet, which is great for medical or outdoor use.

ZOYN is good at making custom solutions. They work with customers to design and make magnets that fit just right, from shape and size to how they are magnetized and put together.

These ways to customize help makers build products that are different from others. That is why injection-molded magnets are a top pick for new designs.

Performance Benefits

Corrosion Resistance

Injection-molded magnetic components do not rust easily. The polymer binder makes a shield around each magnetic particle. This shield keeps water and harmful stuff away from the metal inside. Special coatings, like phosphatizing or silane, make the bond between the powder and polymer stronger. These steps help magnets last longer, even in tough places.

-

The polymer binder keeps magnetic particles apart.

-

Surface coatings help magnets stay strong in bad weather.

-

The smooth surface helps stop chips and cracks.

Tests show these magnets lose less than 5% of their strength after hot water, quick temperature changes, or steam. This makes them great for cars, medical tools, and outdoor gear.

Dimensional Accuracy

Injection molding makes parts very exact. Most parts are made with tolerances close to ±0.005 mm. This happens because of special CNC molds and careful process checks. The process also makes smooth surfaces and even magnetic strength.

|

Feature Size Range (mm) |

Typical Dimensional Tolerance (mm) |

Notes |

|---|---|---|

|

< 3 |

±0.03 |

Small features |

|

3 to 6 |

±0.05 |

Medium small features |

|

6 to 15 |

±0.08 |

Medium features |

|

15 to 30 |

±0.15 |

Larger features |

|

30 to 60 |

±0.25 |

Largest features |

Sintered magnets need extra cutting and grinding. This lowers accuracy and wastes material. Injection-molded magnets are made in one step. This keeps sizes right and cuts down on waste.

Temperature Stability

Injection-molded magnets work well in many temperatures. The binder and powder picked set the highest safe temperature. For example, Nylon 6 magnets can take up to 150°C. PPS magnets can go up to 180°C. SmCo powders are very stable in high heat.

|

Binder / Magnetic Material |

Maximum Operating Temperature |

Notes |

|---|---|---|

|

Nylon 6 (PA6) |

140-150°C |

Common binder for injection molding |

|

Nylon 12 (PA12) |

120-150°C |

Not recommended above 150°C |

|

PPS |

Up to 180°C |

High temperature binder |

|

Ferrite + Nylon 6 |

Up to 150°C |

Good for automotive parts |

|

Ferrite + PPS |

Up to 180°C |

For high-temperature environments |

|

NdFeB (high energy grade) |

Up to 120°C |

Irreversible loss above 120°C |

The right binder and powder mix keeps magnets stable, even when it gets hot.

Low Eddy Current Losses

Injection-molded magnets use tiny powders mixed with plastic binders. This setup breaks up the paths that eddy currents use. Coatings on each particle keep eddy currents small. Because of this, these magnets do not waste much energy as heat. This makes them good for motors and sensors.

-

The plastic binder blocks eddy currents, making magnets work better.

-

Low eddy current loss helps devices stay cool and last longer.

This special structure helps injection-molded magnets work well in fast and high-frequency uses.

Cost and Efficiency

Mass Production

Injection-molded magnetic components are great for making lots of parts. Companies spend money on molds and machines at first, but they save money later. The process is fast and makes many parts that are all the same. These parts are made with high accuracy. Makers can create tricky shapes and close fits that are hard with other ways. This is why injection molding is good for making millions of parts, like in cars, brakes, and electronics.

Injection molding is special because it makes complex magnetic parts quickly and at a low cost.

Reduced Waste

Injection molding makes less waste than old ways of making magnets. It uses just the right amount of material for each part, so there is not much left over. Companies often use leftover bits again, which helps the environment.

-

Magnets help sort waste better, so less goes to landfills.

-

Better sorting helps with recycling and being green.

-

Using leftovers again in magnet making is good for the planet.

-

Less waste means we help the earth more.

-

Using magnets in waste work helps protect nature.

Using materials wisely saves money and helps companies be more eco-friendly.

Assembly Integration

With injection-molded magnets, building things is easier. Makers can put magnets right into plastic parts while molding. This means fewer steps and faster making of products.

-

Insert molding sticks magnets and plastic together, making them strong.

-

Fewer screws or glue are needed, so there are fewer parts and lower costs.

-

Robots help place magnets, making things more exact and saving work.

-

Putting many parts into one molded piece gives more design choices and better results.

For example, in car sensors and vacuums, putting magnets in during molding means no extra steps later. This makes products work better and cost less to make. Getting all parts from one place also makes it easier to keep track and check quality, so everything runs smoother.

Comparison with Traditional Methods

Sintered Magnets

Sintered magnets have been used in motors and electronics for a long time. They are made by pressing and heating magnetic powders until they stick together. This makes them strong, but also easy to break or chip. Injection-molded magnets are made differently. They mix magnetic powder with plastic and shape it in molds. This makes them tougher and less likely to crack.

|

Aspect |

Injection-Molded Ferrite Magnets |

Sintered Ferrite Magnets |

|---|---|---|

|

Ferrite powder mixed with thermoplastic binders and additives, injection molding technology |

Produced like ceramics by sintering ferrite powder |

|

|

Shape Complexity |

Can produce complex shapes |

Limited to simpler shapes (round, ring, tile, cylindrical) |

|

Dimensional Accuracy |

Higher accuracy (±0.08 mm) |

Lower accuracy (±0.1 mm) |

|

Mechanical Durability |

Better drop and wear resistance due to nylon component |

More brittle, less resistant to drop and abrasion |

|

Magnetic Properties |

Lower magnetic strength |

Higher magnetic strength |

|

Temperature Resistance |

Maximum operating temperature around 100-150°C |

High temperature resistance up to 250°C or above 400°C |

|

Typical Applications |

Used where complex shapes, precision, and mechanical durability are needed (motor components, Hall sensors, electronic appliances, precision instruments) |

Preferred where higher magnetic strength and temperature resistance are critical |

Injection-molded magnets can be made into many shapes and sizes. Their plastic part helps them survive drops and scratches. Sintered magnets are stronger but break more easily. They also cannot be made into as many shapes as injection-molded magnets.

Injection-molded magnets let designers make tough parts in many shapes. This is good for products that need both strength and special designs.

Compression Bonded Magnets

Compression bonded magnets are made by pressing magnetic powder and binder together. Then, they are cured to make them solid. This way makes stronger magnets, but shapes are limited. It also takes longer to make them. Injection-molded magnets use melted plastic and magnetic powder. This mix is put into molds to make parts. This method is faster and can make more shapes.

When someone mentions neodymium magnets, most people think of those shiny silver discs used in gadgets or magnetic tools. But there's a lesser-known type—strong material bonded neodymium—that offers surprising flexibility. And if you're in product design, this might just be the quiet hero you've been overlooking.

Not All Magnets Are Rigid and Sharp-Edged

Unlike traditional sintered neodymium magnets, which are strong but brittle, bonded versions are made by mixing magnetic powder with a binding agent like resin. That might sound like a downgrade, but it actually unlocks a whole new world of customization.

Here’s the thing: bonded magnets can be molded. That means you’re not stuck with basic cylinders or rectangles—you can ask for gear shapes, curved strips, even hollow cylinders. And because the material is more forgiving, there’s less risk of cracking during machining or assembly.

Designers Love the Shape Freedom

In traditional magnet setups, engineers often have to design around the magnet. With bonded magnets, it’s kind of the opposite. The magnet can be made to fit your product’s form—whatever that looks like.

For instance, if you’re designing a compact motor that fits into a strangely-shaped housing (think electric toothbrush, drone rotor, or compact cooling fan), you can mold a ring magnet with radial magnetization and complex inner contours. That kind of precision just isn’t feasible with hard sintered magnets.

Magnetization That Matches the Application

Now let’s talk magnetization. Most people don’t realize that magnets aren’t just north and south. In bonded neodymium magnets, you can request custom magnetization patterns—multi-pole, radial, axial, even combinations.

Imagine a motor that needs smooth torque or a sensor that relies on precise pulse signals. A magnetized ring with 8 or 16 poles evenly spaced around it? That’s entirely doable. You get to optimize the magnetic field to suit your needs, not the other way around.

Lightweight and Corrosion-Resistant

Another underappreciated trait: bonded magnets are usually lighter. Because they're partially plastic, they’re not as dense as solid sintered versions. This is a plus in portable electronics, drones, or anything battery-powered.

Also, since the magnetic particles are embedded in resin or polymer, they’re less prone to corrosion, even in moist or semi-aggressive environments. No need for heavy plating or worrying about rust eating away at performance.

Integration and Overmolding Make Assembly Easier

Ever dealt with tiny magnets that have to be glued or slotted into plastic housings? It’s tedious—and not always reliable. With bonded magnets, you can actually overmold them with plastic components or combine them directly with structural parts. That saves time, reduces part count, and improves overall durability.

For example, a company designing a fitness tracker could mold the magnet into the clasp or charging dock, making the product feel seamless and intentional, not pieced together.

Small Batch? No Problem.

Tooling costs for injection-molded magnets are lower than for sintered ones. And if you’re doing a short production run—maybe you’re launching a prototype or niche product—you don’t want to invest in expensive tooling for sintered shapes.

Bonded magnets let you start small, iterate fast, and scale only when needed.

So yes, bonded neodymium ring magnets aren’t quite as strong as their sintered cousins. But in design, strength isn’t everything. Flexibility, shape complexity, magnetic orientation, corrosion resistance, and ease of integration often matter just as much—if not more.

When your product needs to stand out—or fit somewhere unusual—custom bonded neodymium magnet give you the freedom to design the way you want, not the way the magnet forces you to. Contact us to get more products informaition. Our Whatsapp number: +8615167129264 / +8615888988057

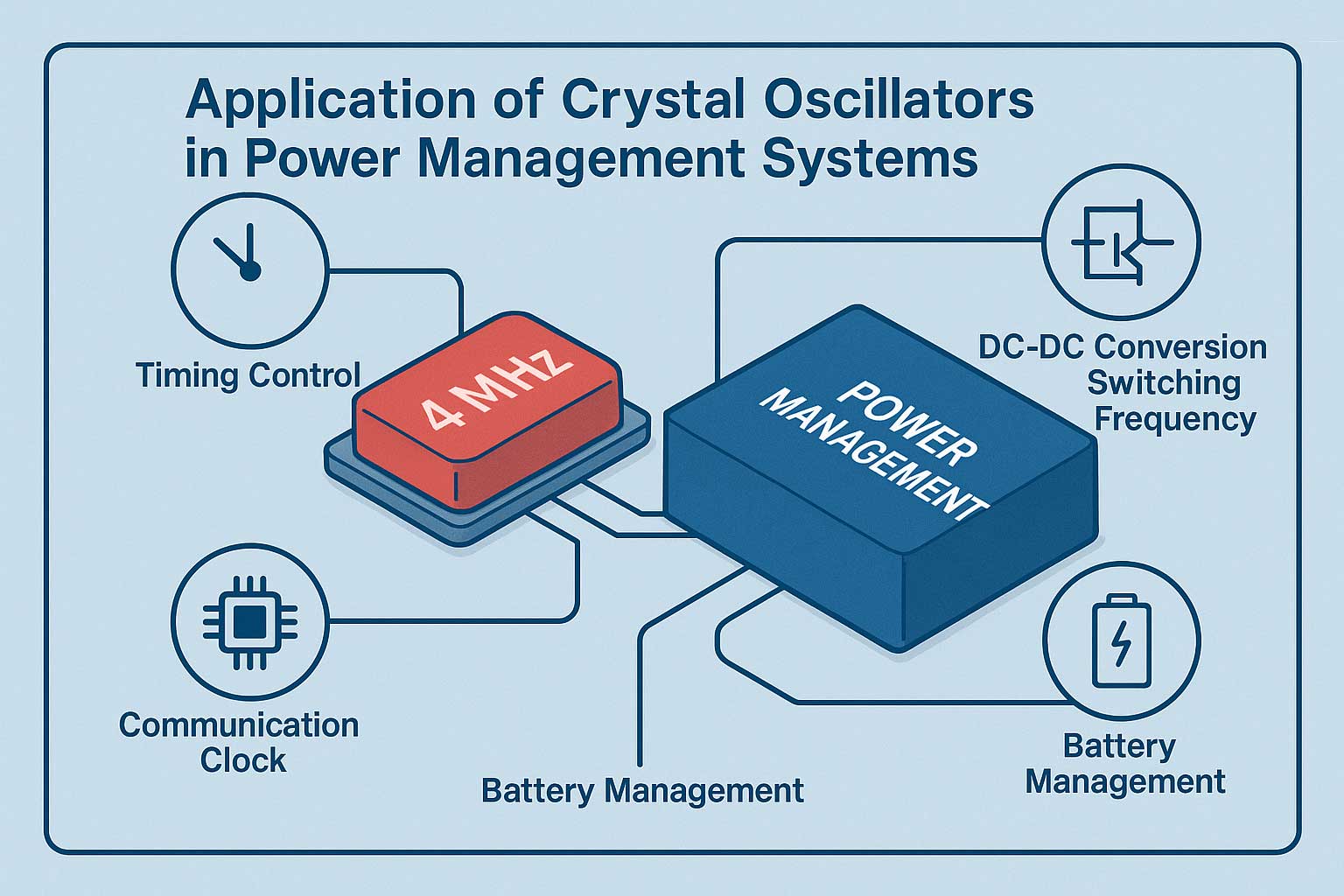

As modern electronic devices become increasingly compact, intelligent, and power-efficient, power management systems (PMS) play a critical role in ensuring stable performance. At the heart of these systems lies an often overlooked component: the crystal oscillator.

At JGHC, we provide high-stability crystal oscillators designed specifically to meet the demands of power management modules across a wide range of industries—from industrial automation and IoT to smart batteries and renewable energy systems.

Why Power Management Systems Need Crystal Oscillators

A crystal oscillator serves as a precise frequency source that ensures accurate timing and system synchronization. In power management modules, it performs the following essential functions:

1.Timing Control for PMICsPower Management ICs (PMICs) rely on an external clock to manage:

- Voltage regulation timing

-

Power-up and shutdown sequences

- Sleep and wake-up cycles in low-power devices

JGHC offers 32.768kHz and MHz-range oscillators ideal for both ultra-low-power and high-frequency control applications.

2. Switching Frequency Stability in DC-DC Converters

Switch-mode power supplies (SMPS), such as Buck or Boost converters, require a stable frequency for:

- Efficient energy conversion

- Reduced electromagnetic interference (EMI)

- Minimizing ripple and thermal losses

A JGHC crystal oscillator ensures that your DC-DC converters run at consistent switching frequencies, even under harsh environmental conditions.

3. Communication Timing for System Interfaces

Most PMS modules support I²C, SPI, CAN, or UART interfaces for communication between microcontrollers, sensors, and battery management systems (BMS). Crystal oscillators:

- Provide accurate baud rate timing

- Enable synchronized data exchange

- Reduce transmission errors

Whether you're designing a smart battery or a power distribution unit, stable communication requires precise clock sources.

Application in Battery Management Systems (BMS)

In BMS modules, oscillators support:

- Periodic sampling of battery voltage, current, and temperature

- Timing triggers for safety monitoring and cutoff

- Accurate timekeeping during system sleep or low-power modes

Our low-power 32.768kHz crystal units are ideal for RTC support, while high-frequency SMD oscillators support real-time data processing in Li-ion battery packs, ESS, and e-mobility applications.

Ideal for Today’s Power-Efficient Innovations

From wearable devices and EVs to solar inverters and energy storage systems, power management is at the core of reliable electronics. Choosing the right crystal oscillator ensures:

- Higher efficiency

- Better timing accuracy

- System longevity and stability

Conclusion

Crystal oscillators are not just passive components; they are precision timekeepers that enable power systems to operate efficiently and reliably. At JGHC, we understand the importance of stability and performance in power-critical applications, and we’re ready to support your next innovation.

Ratchet straps and tie-downs are crucial tools for securing cargo during transportation, providing stability and safety while on the move. To ensure the effectiveness and reliability of these essential devices, standards like EN 12195-2 have been established to guide manufacturers, users, and regulators in the proper selection, use, and maintenance of ratchet straps and tie-downs.

EN 12195-2 is a European standard that specifies the requirements for lashings, web lashings, and ratchets used for the safe transportation of cargo on road vehicles. This standard sets out guidelines for the design, construction, testing, and marking of ratchet straps and tie-downs, aiming to enhance safety and prevent accidents during transport operations.

The standard outlines the design specifications for ratchet straps and tie-downs, including factors such as minimum breaking force, elongation limits, and safety parameters. These design requirements ensure that the straps can withstand the forces exerted during cargo securing without failing.

EN 12195-2 specifies the testing procedures that manufacturers must follow to assess the performance and durability of ratchet straps and tie-downs. This includes tests for strength, elongation, and resistance to environmental conditions to verify compliance with safety standards.

The standard mandates specific marking requirements for ratchet straps and tie-downs, ensuring that essential information such as the manufacturer's details, Lashing Capacity(LC), and safety instructions are clearly displayed on the product. This information helps users select the appropriate tie-down for their cargo and operate it safely.

EN 12195-2 includes recommendations for the maintenance and inspection of ratchet straps and tie-downs to ensure their continued safe use. Regular checks for wear and tear, damage, and proper functioning of the ratchet mechanism are essential to prevent accidents and maintain the longevity of the equipment.

By adhering to the guidelines outlined in EN 12195-2, manufacturers can produce high-quality ratchet straps and tie-downs that meet rigorous safety standards, offering users peace of mind when securing their loads for transportation. Additionally, following these standards allows operators and logistics professionals to choose and use ratchet straps confidently, knowing that they comply with established safety requirements and are designed to withstand the demands of the transport environment.

The EN 12195-2 standard plays a vital role in ensuring the safety and reliability of ratchet straps and tie-downs, promoting best practices in cargo securing and transportation. By understanding and adhering to these standards, stakeholders across the industry can contribute to safer and more efficient logistics operations, reducing the risk of accidents and damage during transit.

- Automotive Engine Rubber Parts8

- Automotive Lamps Rubber Parts5

- Automotive Suspension Rubber Parts2

- Automotive Wiring Harness Rubber Parts3

- Extrusion Sealing Strip1

- Industrial Electrical Rubber Parts3

- Industrial Scanners2

- Industrial electrical control3

- Industrial slings4

- Machine Tool Blades1

- Membrane Products1

- Motor1

- Racecource Rubber Products3

- Rubber Forklift Attachments1

- Rubber and plastic Parts1

- Seal2

- Tubular Motor2

- blade1

- brush1

- chip1

- industrial hose1

- lens1

- mold1

- plc3

- pump2

- racking2