Magnetic shielding is a critical technology used to manage and control magnetic fields, particularly in sensitive environments where electromagnetic interference (EMI) can disrupt equipment performance. While super powerful neodymium magnets are primarily known for their strength, they also play a significant role in creating effective magnetic shielding solutions. Below we explore how neodymium magnets contribute to magnetic shielding and highlight their applications and potential for future development.

The Concept of Magnetic Shielding

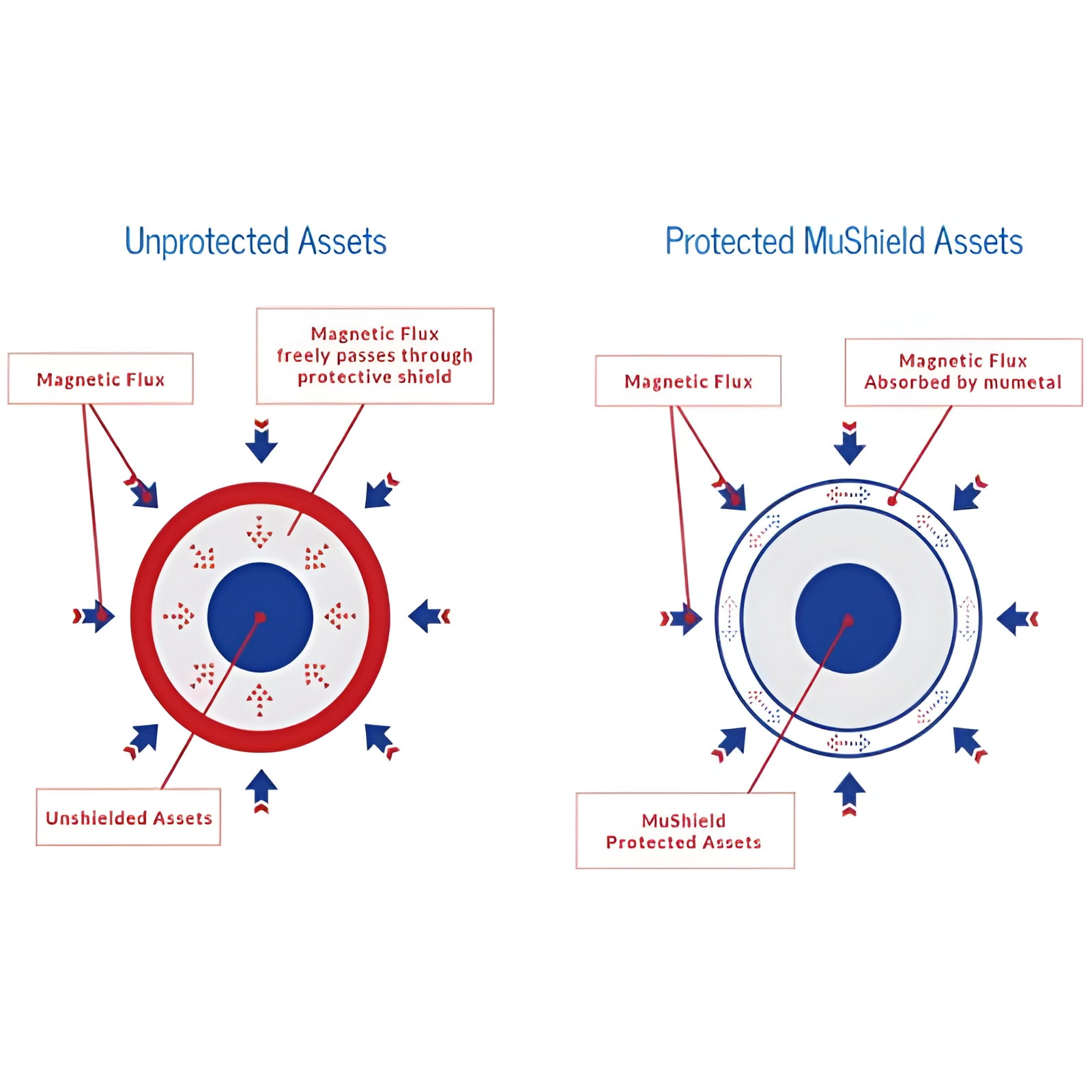

Magnetic shielding is the process of redirecting or reducing magnetic fields to protect sensitive components from interference. It involves the use of materials that can absorb or redirect magnetic flux lines, minimizing their impact on nearby objects. Neodymium magnets, with their strong and stable magnetic fields, are often utilized in conjunction with shielding materials to optimize these effects.

Neodymium Magnets in Magnetic Shielding

One of the key properties of neodymium magnets that makes them suitable for magnetic shielding is their ability to influence and guide magnetic fields effectively. By strategically placing professional custom neodymium magnets, engineers can manipulate the magnetic flux in ways that reduce interference or isolate specific areas. Their compact size and high magnetic energy make them ideal for applications where space is limited, such as in precision electronics and medical devices.

Applications of Magnetic Shielding Using Neodymium Magnets

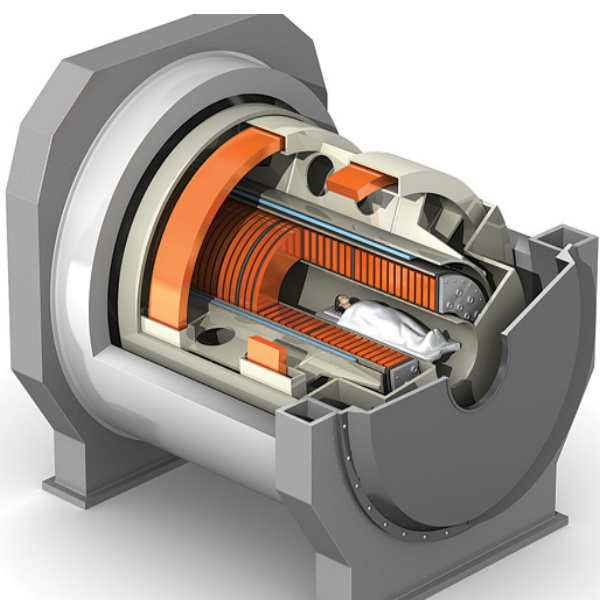

1. Medical Equipment: Magnetic shielding is essential in medical imaging devices like MRI machines. Neodymium magnets help manage stray magnetic fields, ensuring accurate imaging results and protecting nearby equipment from interference.

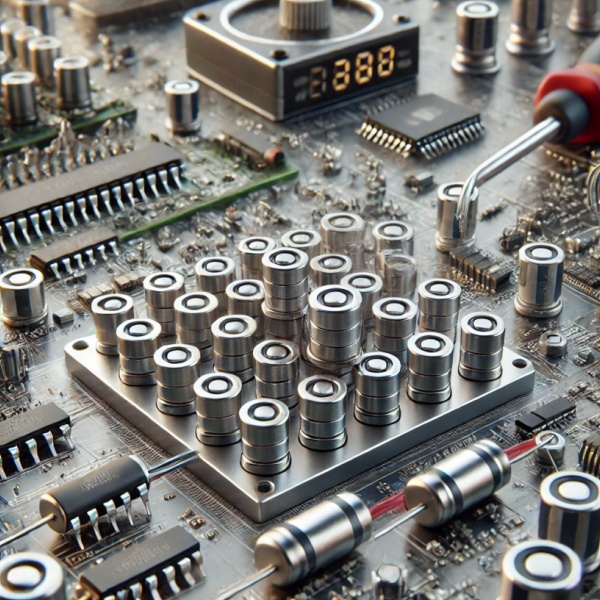

2. Electronic Devices: In modern electronics, shielding is crucial to prevent EMI from disrupting sensitive circuits. Neodymium magnets can be integrated into shielding designs to enhance the effectiveness of the barriers.

3. Scientific Research: In laboratories, neodymium permanent magnets are used in experimental setups requiring controlled magnetic environments. They help minimize external magnetic noise, enabling precise measurements.

Optimizing Magnetic Shielding Designs

To maximize the effectiveness of magnetic shielding with neodymium magnets, engineers often focus on:

- Magnet Arrangement: By carefully arranging magnets, magnetic flux lines can be redirected to minimize interference.

- Combination with Shielding Materials: Pairing neodymium magnets with high-permeability materials like mu-metal or permalloy enhances shielding effectiveness.

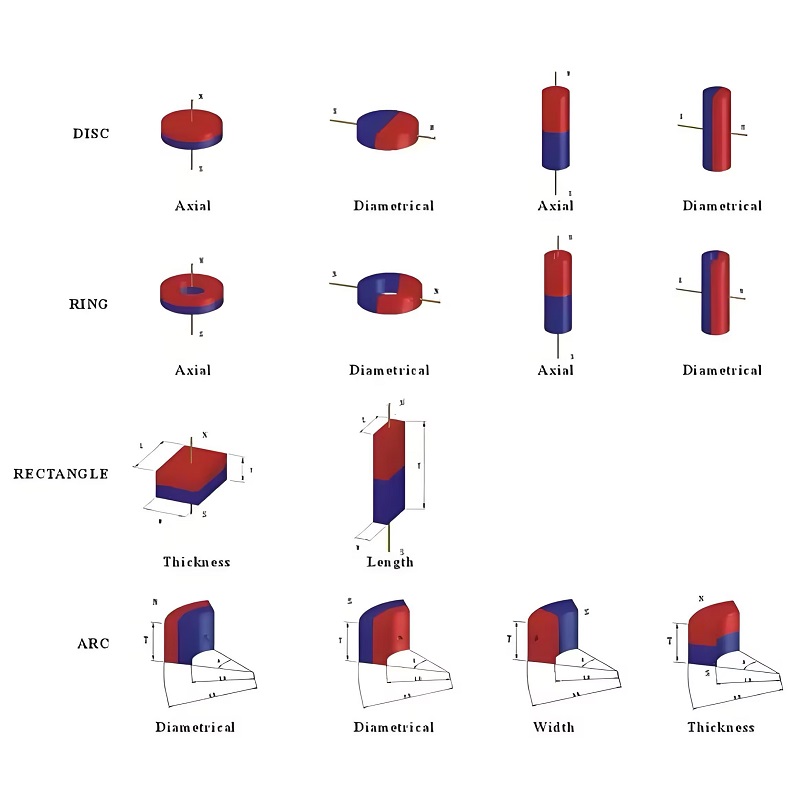

- Custom Shapes and Sizes: Customizing the shape and size of neodymium magnets ensures they fit specific applications, improving both performance and efficiency.

Conclusion

Neodymium magnets are more than just powerful tools for generating magnetic fields—they are also indispensable in the field of magnetic shielding. By leveraging their unique properties, engineers can design innovative solutions to protect sensitive equipment and create controlled environments. As research continues, the role of super quality neodymium magnets in magnetic shielding is set to expand, driving advancements in industries ranging from medicine to aerospace.

Guitar pickups are an essential part of an electric guitar, converting the vibrations of the strings into electrical signals that are amplified and transformed into sound. While there are many types of magnets used in guitar pickups,high performance neodymium magnets have recently gained popularity due to their powerful magnetic properties and smaller size. These magnets play a crucial role in improving the performance of electric guitar pickups, enhancing sound quality, and providing more dynamic range.

Neodymium is a rare-earth metal known for its exceptional magnetic strength, which allows pickups to capture a stronger signal from the guitar strings. This allows guitarists to achieve clearer, more defined tones while preserving the subtleties of their playing.

One of the key benefits of using neodymium magnets in pickups is the improvement in output. The stronger magnetic field can create a higher voltage in the coil of the pickup, which results in a higher output signal. This is particularly beneficial for guitarists who need a more powerful sound for genres like rock, metal, or punk, where higher output and punchier tones are often desired. Additionally, small size ndfeb magnets can offer better sustain and clarity, allowing for longer-lasting notes and more expressive playing.

Furthermore, neodymium magnets are smaller and lighter than traditional magnets, which allows for more versatile designs in pickups. Manufacturers can create pickups with more intricate designs or reduce the overall weight of the guitar while maintaining the desired sound quality. This is especially important for players who value comfort and want to reduce the overall weight of their instrument without compromising on sound.

In conclusion, strong durable neodymium magnets have revolutionized the way guitar pickups function, offering powerful magnetic fields in a compact form. These magnets enhance sound quality, improve output, and provide greater design flexibility, making them a valuable choice for modern electric guitars. Whether it's for a more powerful sound or enhanced tonal clarity, neodymium magnets play a pivotal role in shaping the performance of guitar pickups.

Neodymium magnets, known for their exceptional strength, are a marvel of modern material science. But what gives these magnets their unparalleled magnetic properties? The answer lies in the hidden physics of their composition and structure.

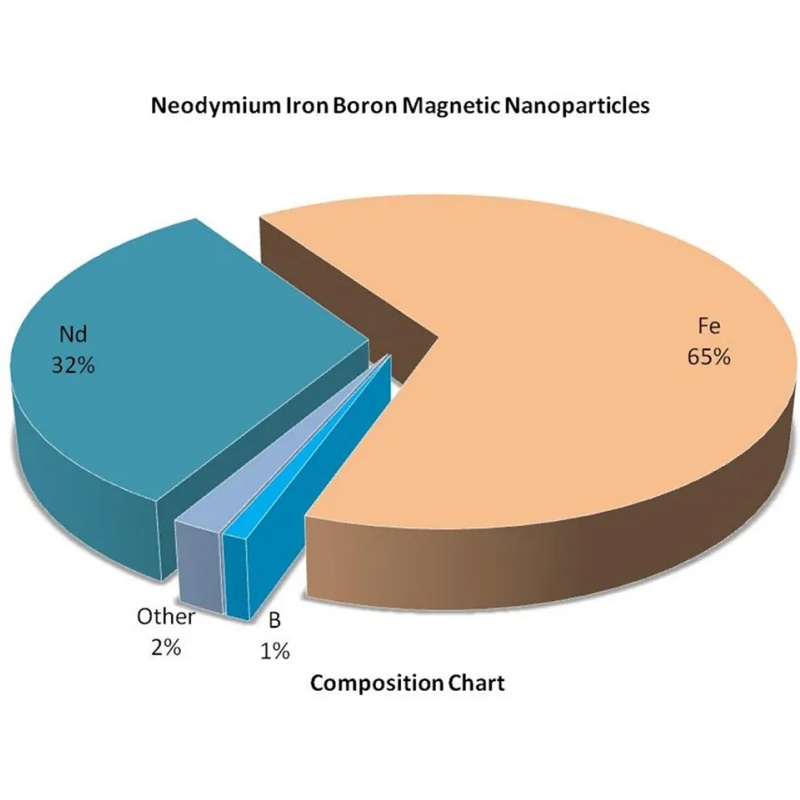

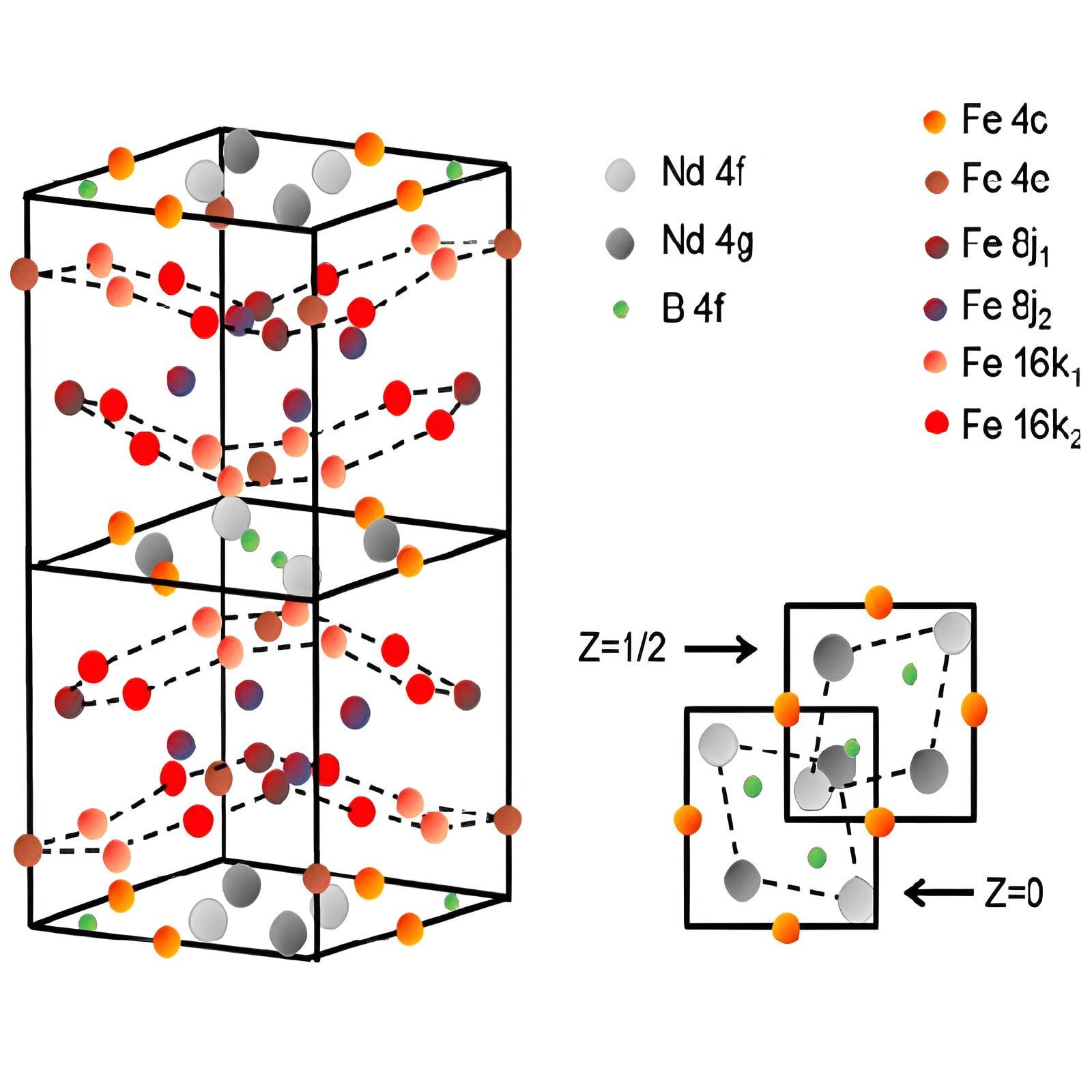

The core of high strength neodymium magnets lies in their unique material composition: a combination of neodymium, iron, and boron (NdFeB). The neodymium atoms in this alloy have a large number of unpaired electrons in their outer shell. These unpaired electrons create strong magnetic moments due to their spin, a quantum mechanical property that generates tiny magnetic fields. When these magnetic moments align in the same direction, they produce a powerful collective magnetic field.

A key concept in understanding neodymium magnets is the behavior of magnetic domains. Inside the magnet, billions of tiny regions, called domains, each have their magnetic moments aligned. In non-magnetic materials, these domains are randomly oriented, canceling out their magnetic effects. However, in neodymium magnets, the domains are meticulously aligned during manufacturing through a process called magnetization. This alignment maximizes the overall magnetic strength.

The crystal structure of neodymium magnets also plays a crucial role. Strong performance neodymium magnets have a foursquare crystal structure, which provides strong resistance to the movement of magnetic domains, known as coercivity. This characteristic ensures that the magnet retains its magnetic properties even under external stress or exposure to opposing magnetic fields.

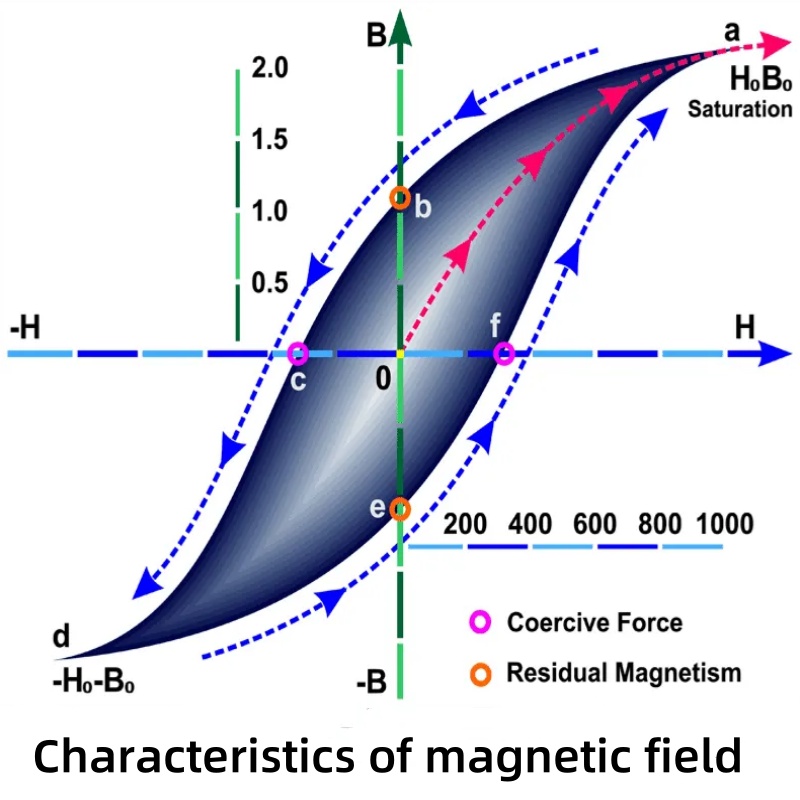

Another critical aspect of neodymium magnets is their magnetic hysteresis loop. This loop represents the relationship between the magnetizing force applied to the magnet and the resulting magnetic field. Neodymium magnets exhibit a wide hysteresis loop, indicating high coercivity and the ability to maintain strong magnetism over time. This feature makes them ideal for demanding applications, such as in electric motors, wind turbines, and medical devices.

In conclusion, the extraordinary strength of neodymium magnets is the result of their quantum mechanical origins, precise domain alignment, and robust crystal structure. These hidden physics principles not only make powerful permanent neodymium magnets indispensable in modern technology but also continue to drive advancements in material science and engineering. By delving deeper into the physics behind these magnets, researchers can unlock new potentials and applications for this fascinating material.

Neodymium magnets, often referred to as rare-earth magnets, are widely used in various electronic devices, including computer hard drives. These magnets are made from an alloy of neodymium, iron, and boron, creating a strong magnetic field that plays a crucial role in the operation of modern hard drives.

The primary function of neodymium magnets in hard drives is to help position the read/write heads accurately. Hard drives consist of rotating disks coated with magnetic material, and the read/write heads are responsible for reading and writing data onto the disk. These heads must be precisely positioned above the spinning disks, and high strength neodymium magnets play a critical role in this process. They are used in the actuator arm mechanism, which moves the read/write heads across the disk's surface. The strong magnetic field generated by the neodymium magnets allows the actuator arm to move swiftly and accurately, ensuring that the heads are aligned with the correct data tracks on the disk.

In addition to providing accurate positioning, neodymium magnets also help in the overall efficiency and miniaturization of hard drives. The high magnetic strength of small powerful neodymium magnets enables the actuator arm to be smaller and lighter, which contributes to the compact design of modern hard drives. Smaller hard drives, in turn, have faster data access speeds, lower power consumption, and increased reliability.

Furthermore, the use of neodymium magnets in hard drives is essential for maintaining the stability and integrity of the data stored on the disks. By ensuring precise head positioning, these permanent rare earth ndfeb magnets help prevent errors during the reading and writing processes, thus reducing the likelihood of data corruption or loss.

In conclusion, neodymium magnets play a vital role in the operation of computer hard drives. Their strong magnetic properties enable precise movement of the read/write heads, enhancing the speed, reliability, and efficiency of data storage systems. As technology continues to advance, the role of these magnets will remain crucial in ensuring the performance and miniaturization of future hard drives.

Permanent powerful neodymium magnets, are renowned for their exceptional magnetic strength and versatility. These magnets are widely used in various industries, ranging from electronics and automotive to healthcare and renewable energy. A critical aspect of their performance lies in their magnetization direction and orientation direction. Understanding and optimizing these directions are essential for achieving the desired functionality and efficiency in applications.

The magnetization direction refers to the alignment of magnetic domains within the magnet, determining the poles (north and south). High quality eodymium magnets are anisotropic, meaning their magnetic properties are stronger in a specific direction. This makes it crucial to align the magnetization direction correctly during production to suit the intended application. For instance, in motors or generators, improper magnetization direction can lead to reduced performance or failure.

Similarly, the orientation direction plays a vital role in determining how the magnet interacts with external forces. During the manufacturing process, high temperature resistant neodymium magnets are typically sintered and pressed under a magnetic field to achieve the desired orientation. This ensures that the magnetic domains are optimally aligned, resulting in maximum magnetic strength. If the orientation is incorrect, the magnet's efficiency can significantly decrease, affecting its ability to perform tasks such as lifting, holding, or transmitting torque.

The importance of these directions becomes evident in high-precision applications. For example, in magnetic resonance imaging (MRI) machines, the durable strong ndfeb magnets must maintain a uniform magnetic field for accurate imaging. Similarly, in loudspeakers, the alignment of the magnet's poles directly impacts sound quality. Even minor deviations in magnetization or orientation can lead to noticeable performance issues.

In conclusion, the magnetization and orientation directions of neodymium magnets are pivotal to their functionality. By optimizing these factors, industries can harness the full potential of these powerful magnets, ensuring superior performance and efficiency in diverse applications.

Webbing slings are widely recognized for their versatility, durability, and ease of use in various lifting applications. However, it is essential to consider several factors to ensure safe and efficient lifting operations. In this blog post, we will explore the key factors that need to be considered when using webbing slings for lifting. By understanding these factors and implementing them effectively, you can enhance safety, prolong the lifespan of the slings, and optimize your lifting processes.

The Working Load Limit is the maximum weight that a webbing sling is rated to safely lift under normal operating conditions. It is crucial to determine the WLL required for your specific lifting task. Consider factors such as load weight, load distribution, angles, and any additional forces that may be applied during the lift. Always ensure that the WLL of the webbing sling exceeds the weight of the load being lifted to maintain a safe working environment.

Webbing slings are typically made from high-strength synthetic fibers such as polyester or nylon. Evaluate the specific requirements of your lifting operation to choose the most suitable material. Polyester slings are known for their low stretch and high resistance to abrasion, while nylon slings offer excellent flexibility and shock absorption. Assess the environmental conditions, load characteristics, and chemical exposure to make an informed decision about the material and construction of the webbing sling.

Regular inspection and maintenance of webbing slings are crucial to ensure their safe and reliable performance. Inspect the slings for any signs of wear, cuts, abrasion, or damage before each use. Verify that the slings are free from knots, twists, or any other deformities that may compromise their strength. Clean the slings as per the manufacturer's guidelines, and store them properly in a clean and dry environment when not in use. Adhering to proper inspection and maintenance practices will contribute to the longevity and safety of the webbing slings.

Proper usage and rigging techniques are of paramount importance for safe lifting operations. Ensure that the webbing slings are correctly attached to the load using appropriate hitches or attachments. Pay attention to load balance and distribution to prevent stress concentrations on specific points. Use edge protectors to safeguard the sling from sharp edges or rough surfaces. Train personnel on proper sling handling techniques, including avoiding sudden movements and maintaining clear communication during lifting operations.

Adhere to relevant safety standards and regulations when selecting and using webbing slings. Familiarize yourself with industry-specific guidelines and local regulations governing lifting operations. Ensure that the webbing slings you use are certified and comply with recognized standards, such as EN 1492-1 or ASME B30.9. Regularly review and update your lifting procedures to align with the latest safety requirements.

When using webbing slings for lifting, considering key factors such as the Working Load Limit, material and construction, ongoing inspection and maintenance, safe usage, and compliance with safety standards is essential to ensure maximum safety and performance. By prioritizing these factors, you can minimize risks, enhance productivity, and optimize your lifting operations. Remember to consult with experts or manufacturers for specific guidance tailored to your lifting requirements, and always prioritize safety in every step of the lifting.

Choosing the best casters for outdoor use involves considering durability, load capacity, maneuverability, and resistance to outdoor elements. Outdoor casters are essential for applications like moving furniture, equipment, or garden structures, where they need to withstand uneven surfaces, moisture, and temperature changes. Here’s a quick guide to choosing the right caster for outdoor use.

Material

Outdoor casters are typically made from durable materials that can endure harsh environments. Swivel stainless steel casters, for example, are corrosion-resistant and can withstand moisture, while polyurethane casters provide a smooth roll over rough surfaces and resist damage from chemicals, oils, and abrasions.

Industrial rubber casters are also popular for outdoor use due to their flexibility and ability to handle rough and uneven ground. Hence, cast iron casters are not suitable for outdoor use.

Tread Type

A soft-tread one, such as rubber or polyurethane, shock absorbing casters from uneven surfaces, making it suitable for outdoor use. Soft-tread casters also provide good traction on wet surfaces, reducing the risk of slipping. For heavy-duty tasks, consider casters with pneumatic (air-filled) tires, which offer excellent cushioning and grip on varied terrains.

Top Recommendations

Polyurethane Casters: Known for durability and smooth operation, polyurethane casters handle rough outdoor surfaces well and are resistant to various chemicals, making them ideal for gardens and outdoor warehouses.

Stainless Steel Casters: Perfect for environments where moisture is a concern, these casters resist rust and are suited for outdoor furniture and equipment that might be exposed to rain or snow.

Pneumatic Casters Wheels: Equipped with air-filled tires, these are ideal for heavy-duty applications on rough or uneven ground. They offer great shock absorption, making them suitable for outdoor activities and construction sites.

When selecting casters for outdoor use, consider the specific environment and load requirements to ensure safety and longevity.

When choosing a Heavy Duty Outdoor Caster Wheels, there are several important factors to consider:

Wheel Grip

Excellent grip is essential when choosing wheels that can carry heavy loads outdoors,such as Heavy Duty Industrial Trolley Wheels. These wheels are usually designed for high performance, have excellent shock absorption, and can easily navigate rough or uneven surfaces.

Turning Radius

The turning radius refers to the amount of space required for the reel to swing or turn. For Outdoor Industrial Metal Casters, choosing a larger turning radius reduces the force required to change direction, providing smoother, more efficient movement.

Maneuverability

Efficient maneuverability is especially important for outdoor spaces. Heavy-duty swivel wheels allow for greater flexibility and smoother movement than fixed casters. For precise control, consider a swivel lock or heavy duty kingpinless casters design that eliminates pan head errors and provides greater steering accuracy.

Load Capacity

Before choosing a heavy duty caster, it is important to understand the total load capacity of the caster set. This includes not only the weight of the object, but also the weight of the cart or equipment the pulley is attached to.

Conclusion

These are the most important considerations when choosing a heavy-duty outdoor caster. YLcaster is one of the leading industrial casters and wheels manufacturers in China, offering a wide range of options to suit every need.

Visit our website to learn more about our quality casters and feel free to contact us for expert advice and recommendations on the solution that best suits your industrial needs.

The latest trends in furniture caster wheels revolve around smart features, sustainability, customization, and functionality. Smart casters integrate sensors for motion detection and automatic locking, while eco-friendly materials like recycled plastics and bamboo are increasingly used to align with sustainability goals. Customization options such as varied colors and designs cater to individual tastes and interior decor styles.

Furniture casters for hardwood floors with noise reduction features like rubberized treads or specialized designs aim to minimize disturbances. Multi-functional casters enable furniture pieces to transform easily, optimizing space in smaller living environments. Minimalist designs with clean lines are favored, ensuring casters blend seamlessly with modern furniture aesthetics.

In industrial and commercial settings, heavy-duty casters made from advanced materials like high-strength steel alloys cater to transporting heavy loads, often incorporating swivel locks and brake systems for safety. Additionally, there's a growing demand for antimicrobial casters, particularly in healthcare and hospitality sectors, to enhance hygiene and reduce the spread of pathogens. These trends reflect a combination of consumer preferences, technological advancements, and a focus on sustainability and functionality in furniture design.

Choosing the right caster is essential to ensure that your furniture can be moved easily and safely.

If you find a reliable caster wheel manufacturer, you can also get discounts on bulk orders.

How to Choose the Best Furniture Casters?

Furniture casters are new territory for many people. You might be surprised at how many factors affect their performance.

Here are some helpful tips to help you choose furniture casters easily and safely:

Consider the type of floor

The type of floor you use your furniture on is crucial. Different floors require different actions. For example, polyurethane or padded rubber casters,Nylon Casters For Hardwood Floors are great for wood, granite, or tile floors because they provide good grip, run quietly, and prevent damage to the floor.

Determine the Weight of the Furniture

Another important factor is the weight of the furniture. Heavier furniture usually requires casters with a higher load capacity. However, you don't always need Heavy Duty Industrial Trolley Wheels, especially for lightweight furniture like tables or office chairs. In fact, using heavy duty wheels that are too heavy for lighter furniture can cause unnecessary damage to the floor. Therefore, estimate the weight of your furniture and choose such Dining Room Chairs Caster Wheels that can adequately support it.

Measure the diameter and width of the tread

The diameter of the wheel can significantly affect the mobility and stability of your furniture. Larger wheels are easier to roll, and they are ideal if you move your furniture frequently. On the other hand, Small Fixed Casters provide more stability and keep the furniture stationary. Therefore, the choice of diameter should depend on how easily you want your furniture to be moved or stationary.

Evaluate your options carefully

Before buying furniture casters, it is important to consider all your options. The right casters will make your furniture more functional and comfortable, while the wrong choice can hinder mobility or even make it unusable.

Conclusion

Knowing the basics of casters will help you choose the type that best suits your needs. Choosing the right casters can improve the functionality of your furniture and make a noticeable difference in your daily life.

- Automotive Engine Rubber Parts8

- Automotive Lamps Rubber Parts5

- Automotive Suspension Rubber Parts2

- Automotive Wiring Harness Rubber Parts3

- Extrusion Sealing Strip1

- Industrial Electrical Rubber Parts3

- Industrial Scanners2

- Industrial electrical control3

- Industrial slings4

- Machine Tool Blades1

- Membrane Products1

- Motor1

- Racecource Rubber Products3

- Rubber Forklift Attachments1

- Rubber and plastic Parts1

- Seal2

- Tubular Motor2

- industrial hose1

- mold1

- plc2

- pump1

- racking2